The HTM90D Load and Brake Module attaches to the HTM90 base unit to simulate a system under load. This enables the students to observe the vibrational affects produced at different speeds and load forces. The module creates the vibrations as a function of torque and resistance.

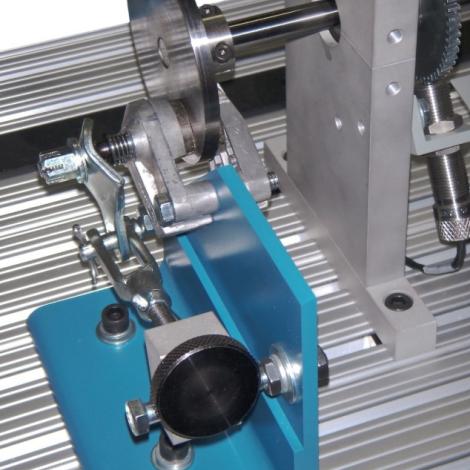

The module consists of a brake and disc attachment to the main HTM90 base unit. The braking torque can be adjusted on the control unit via a clamping knob, different breaking forces can be finely adjusted for any part of the experimental procedures.

The brake can be quickly and precisely mounted on the grooves of the base unit and tightened into position. This module can be used as an extension to experiments on various alternative HTM90 series setups and can constitute as an added variation to several of the module setups.