The HPM15 Interface has been designed to function with UTM Magnus (HPM) experiments fitted with appropriate transducers. It has the facility to display, record, store and review parameters of strain, pressure, force and deflection and can be operated in two modes; with PC (USB) or without PC (Standalone).

The unit is a fully integrated data acquisition / signal conditioning interface. Each of the 23 channels has its own signal conditioning. The variables, either displayed on the internal LCD, or PC software, are returned as 'real world' values of either microstrain, Force (N), Pressure (bar) or deflection (mm) making it very user friendly. The local display, along with the USB PC connection, make this a highly flexible and versatile unit for any application.

The unit also has the ability to operate with bespoke customer experiments which use appropriate transducers.

The HPM15 includes 16 channels for either strain or Force or any combination of the two up to 16 maximum, 6 dial gauge inputs, and one pressure input.

It has a front fascia 4 line display, which displays the parameters in standard engineering units. Front fascia buttons also allow the end user to tare the displayed values. Connections to the hardware transducers are made via external sockets surrounding three sides of the interface unit. Mating connectors are either factory fitted to the hardware transducer cables, or can be fitted by the end user.

The interface is powered via a universal voltage power supply with removable plug adaptors for different countries.

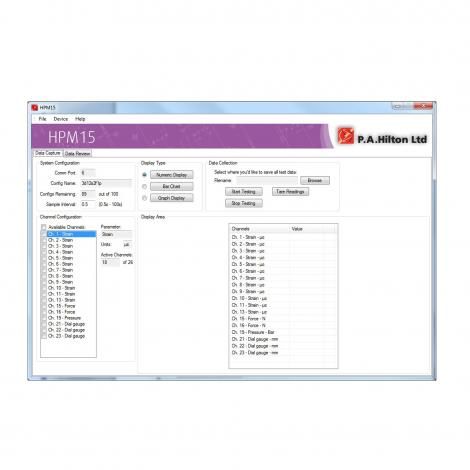

The HPM15 software supplied has been designed to capture the data from the HPM15 interface. This captured data is displayed live in a variety of different formats including graph, numerical, or bar, and is stored on-board. Retrieval of the data for reviewing is available, along with exporting to other applications.

The software also allows for bespoke channel configuration, when customers wish to use the interface and software with their own experiments.