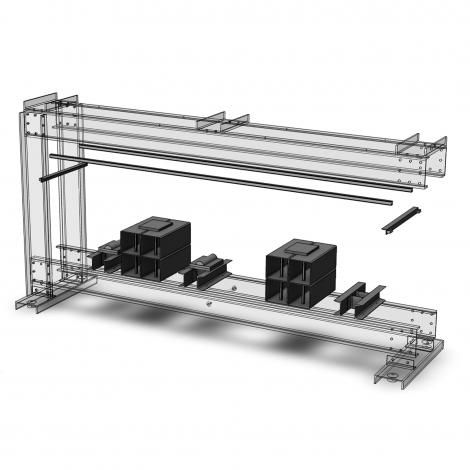

Two double acting hydraulic rams are mounted on their own individual travelling carriages. The wheels of the carriage roll on the bottom flanges of the horizontal upper cross member of the HPM1 “MAGNUS” Universal Test Frame and clamping screws and hand wheels are provided to lock the carriage where required. This enables the loading span to be varied accordingly.

The hydraulic rams are simultaneously operated using a 700Bar hand pump, which is mounted on a mobile table. A manually operated shut off valve at the end of the hand pump controls the travel direction of the rams, and stabilisation of the load. A digital pressure indicator shows the system pressure, and hence ram pressure via a transducer. The digital display is calibrated in “psi”. The digital indicator can be moved around the hydraulic table and tilted to give a better viewing angle.

The hydraulic table has an integral shelf to store accessories. Each ram is connected using two 4 metre flexible hoses with self-sealing couplings are provided. One hose for the raising side and another for lowering.

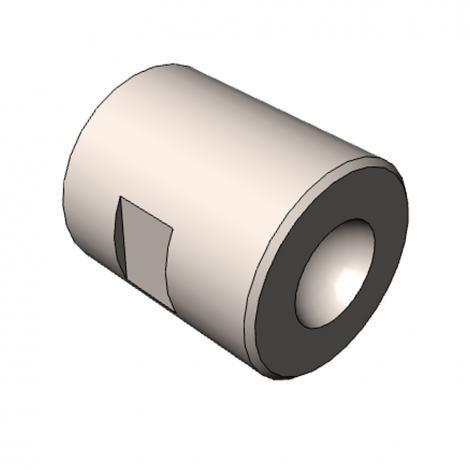

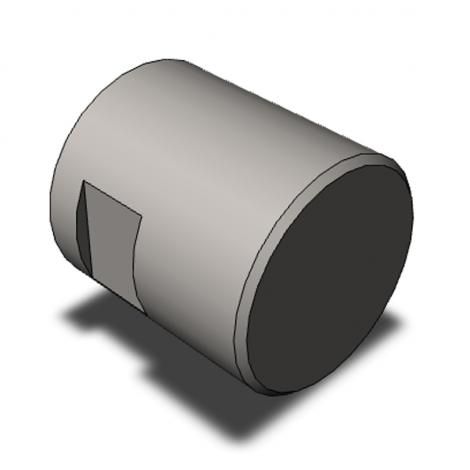

The stroke of the hydraulic rams are upto 250mm. An additional extension of 250mm is supplied for each ram and can be fitted to bring the test specimen closer to the rams. Additional accessories are also supplied to give both a "flat" contact point and "point" contact point.