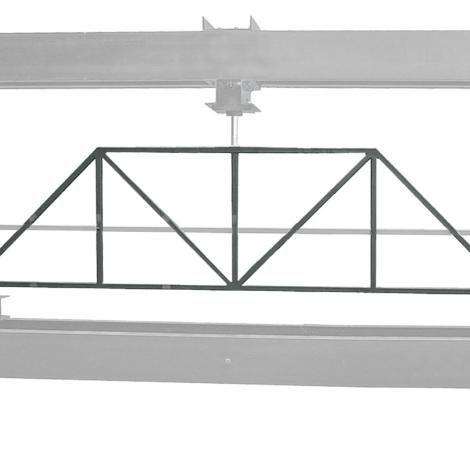

The standard truss supplied is made from fully welded hollow square section steel members and has dual end bearings so that it can be mounted in the normal manner or inverted.

Two high level reaction supports are supplied to allow the truss to be inverted and to use the same end bearing conditions.

One end of the truss is pinned to permit rotation and the other end pinned incorporating a triple roller system to eliminate horizontal restraint

The truss has been specially designed to be tested in the MAGNUS (HPM1) frame with hydraulic loading and deflections measured using the dial gauges supplied.

The standard set of accessories that are supplied with the HPM1, allow the dial gauge to be positioned accurately at the joints. For safety reasons during experimentation, two safety chains have been provided to secure the truss to the HPM1 MAGNUS frame, whilst not restricting the truss movements or deflections.